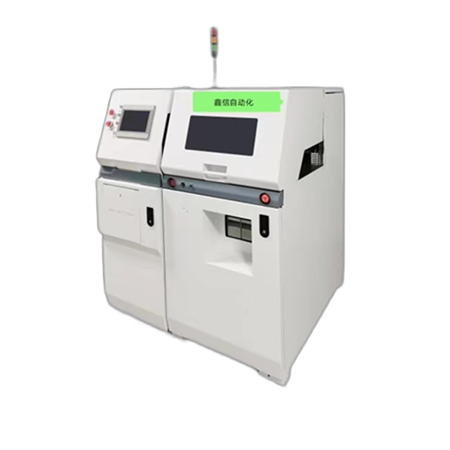

Vertical powder forming machine: an efficient and precise industrial manufacturing tool

2024-11-14 9:31:56

In the rapid development of modern manufacturing, vertical powder forming machine, as an advanced manufacturing process equipment, is playing an increasingly important role. This article will introduce the working principle, application field and unique advantages of vertical powder forming machine in detail to help you better understand this industrial manufacturing tool.

Working Principle

Vertical powder molding machine mainly applies huge pressure to powder materials through hydraulic system or mechanical pressure system to compress and mold them in the mold. The specific process is as follows:

Powder filling: Add powder materials such as metal, ceramic, plastic, etc. to the mold of the forming machine.

Pressure application: Applying pressure to the powder through the hydraulic system or mechanical pressure system of the machine to compress and mold it in the mold.

Maintaining pressure: Maintaining a certain pressure for a period of time to ensure that the powder material forms a stable molding structure in the mold.

Release mold: After the pressure is released, the molded powder product is removed from the mold. This step requires careful handling to avoid damaging the molded part.

Depending on the requirements, the molded powder product may also need to be sintered, heat-treated or subjected to other post-processing to improve its mechanical properties and stability.

Applications

Vertical powder forming machines are widely used in many industrial fields due to their high efficiency and precise manufacturing capabilities:

Mechanical manufacturing: Used to manufacture various complex metal parts such as gears, bearings, etc.

Medical devices: In medical device manufacturing, powder forming technology is used to produce high-precision products such as artificial joints and dental implants.

Electronic Industry: Used to manufacture the base or housing of electronic components to ensure their dimensional accuracy and mechanical strength.

Ceramic Industry: Manufacture of various ceramic products such as tiles, tableware, etc.

Powder Metallurgy: In the field of powder metallurgy, powder forming machines are used to produce various high-strength and high-temperature resistant parts.

Automobile industry: Used to manufacture engine parts, brake system components, etc. to improve the performance and reliability of automobiles.

Advantages and Features

The reason why vertical powder forming machines can be widely used in many fields is due to their unique advantages:

High efficiency and energy saving: The use of advanced mechanical, electrical, hydraulic, gas and instrumentation integrated control and drive technology has greatly improved production efficiency and reduced energy consumption.

High precision: The equipment has a simple structure, is easy to operate and maintain, and can produce high-precision powder products.

High versatility: The action program of each product step drive component can be flexibly set via the touch screen without changing the internal program, and is suitable for molding a variety of powder materials and complex shapes.

Stable and reliable: The equipment is reasonably designed, formed by steel plate welding, with good mechanical rigidity and high precision, ensuring the stability and reliability of the product.

Easy to maintain: The equipment adopts an upper drive mode, with less transmission loss, a small installation site, and easy maintenance and service.

In summary, the vertical powder forming machine plays an important role in many industrial fields with its efficient, precise, stable and reliable manufacturing capabilities. In the future, with the continuous advancement of technology and the continuous expansion of applications, the vertical powder forming machine will bring more surprises and opportunities to industrial manufacturing.

Latest News

- Powder moulding machine selection guide: how to choose the right equipment for your production needs

- There are many factors to consider when selecting a powder moulding machine to ensure that the equipment selected will meet production requirements. The followi...

- Dressing and forming equipment: a tool to ensure part accuracy and quality?

- Dressing and forming machines play a vital role in the manufacturing industry. Through a series of precise mechanical operations, they ensure that workpieces me...

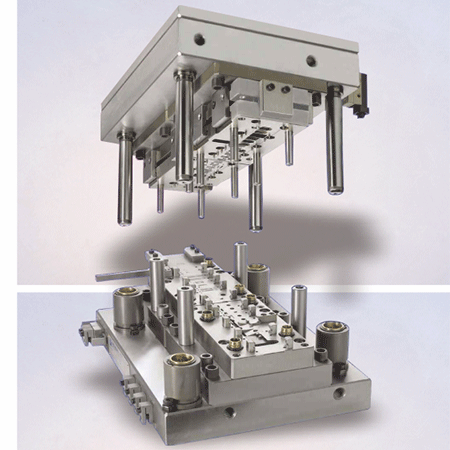

- Powder Metallurgy Mold: A Key Component in the Metal Forming Process

- Powder metallurgy dies are an essential key component in the metal forming process. They use powder metallurgy technology to press metal powder into shape and t...

- Powder metallurgy mold: the core of efficient metal forming process

- Powder metallurgy mold, as a key component in the metal forming process, is becoming an indispensable and important tool in the manufacturing industry with its ...

- Plastic Packaging Equipment: Shaping the Green and Innovative Packaging of the Future

- In today's rapidly developing packaging industry, plastic packaging equipment has become the first choice for many companies due to its high efficiency, flexibi...