The Precision Power of CNC Powder Molding Press: Revolutionizing Manufacturing

2023-12-22 7:50:20

Introduction:

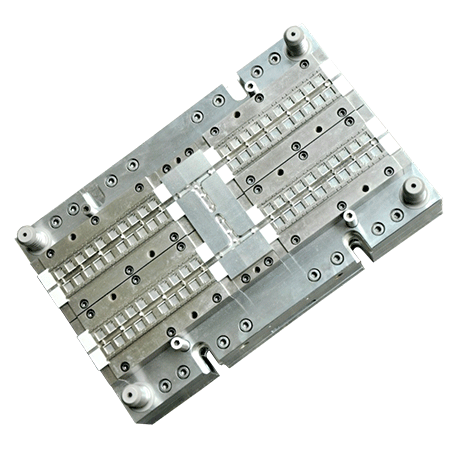

In the ever-evolving landscape of manufacturing, the CNC powder molding press stands out as a game-changer, bringing precision and efficiency to the production floor. This advanced technology merges the capabilities of CNC machining with powder metallurgy, promising unparalleled accuracy and intricate detailing in the fabrication of metal components.

Benefits:

Precision Redefined: The CNC powder molding press delivers exceptional precision in shaping metal powders into complex and detailed components. The computer-controlled process ensures accuracy down to the micron, meeting the most stringent requirements.

Efficient Material Utilization: The CNC-driven approach optimizes material usage, minimizing waste in the powder metallurgy process. This not only aligns with sustainability goals but also contributes to cost-effectiveness.

Versatility in Material Handling: From ferrous to non-ferrous metals and even advanced alloys, the CNC powder molding press accommodates a wide range of materials. This versatility allows manufacturers to meet diverse industry needs.

Reduced Production Time: The automated nature of CNC processes significantly reduces production time. Quick tool changes, precise movements, and high-speed operations translate to faster turnaround, critical in today's dynamic market.

Intricate Designs with Ease: Complex geometries and intricate designs that were once challenging are now achievable with a CNC powder molding press. This capability opens new possibilities in product design and innovation.

Challenges:

High Initial Investment: Implementing a CNC powder molding press involves a significant upfront investment. However, many manufacturers find the long-term benefits outweigh the initial costs.

Skill Requirement: Operating and programming CNC machinery demands skilled personnel. Companies may need to invest in training or hire skilled professionals to harness the full potential of this technology.

Maintenance Complexity: CNC systems, including powder molding presses, require regular maintenance. Ensuring optimal performance involves a proactive approach to maintenance, which can be perceived as a challenge by some.

Case Studies:

Aerospace Component Manufacturing: In the aerospace industry, the CNC powder molding press has been instrumental in crafting lightweight and high-strength components. The precision offered by this technology meets the stringent standards of the aerospace sector.

Medical Device Production: The medical industry benefits from the intricate detailing capabilities of the CNC powder molding press. Production of orthopedic implants and other critical medical components has seen improvements in both precision and efficiency.

Automotive Innovation: CNC powder molding press plays a role in the automotive sector's pursuit of lightweight and fuel-efficient designs. Components with complex structures and optimal strength are now achievable with this technology.

Conclusion:

CNC powder molding press represents a paradigm shift in metal component manufacturing. Its ability to blend precision with efficiency, coupled with versatility in material handling, makes it a cornerstone technology in diverse industries. While challenges exist, the benefits and success stories from various sectors underscore its transformative impact on modern manufacturing. As technology advances, the CNC powder molding press is poised to continue shaping the future of precision manufacturing.

Latest News

- Cold heading dies: exquisite craftsmanship and excellent quality

- As an important tool in the field of metal processing, cold heading dies have always attracted much attention in the industry for their exquisite craftsmanship ...

- Semiconductor molds: the heart of precision manufacturing

- Semiconductor molds play a critical role in the semiconductor manufacturing industry, and their quality and precision are directly related to the performance an...

- What are the key features of the test packaging machine?

- As an instrument specially designed to test the performance of packaging materials or finished packages, the test packaging machine has many key features that e...

- Multifunctional magnetic core processing machine: a technological model of precision manufacturing

- Multifunctional magnetic core processing machine, as an important equipment in the field of modern magnetic material processing, has become an indispensable too...

- In-depth analysis of cold heading die manufacturing technology

- Cold heading die manufacturing is a key technology in the field of metal processing. It involves several links, such as die design, material selection, manufact...