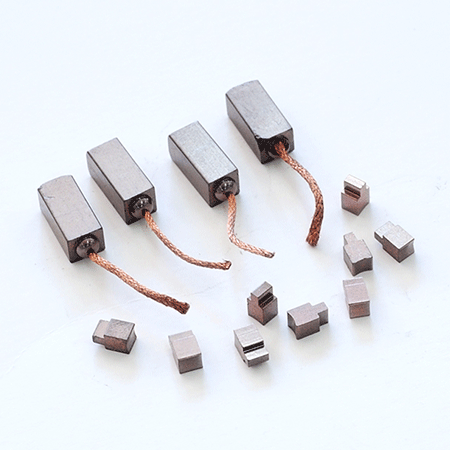

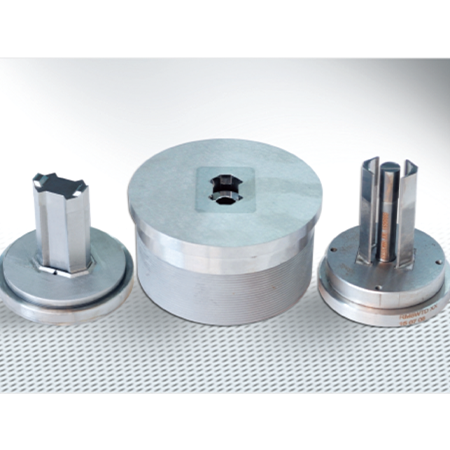

Trimming and forming fittings

What are molded accessories?

Molded accessories are parts that are manufactured using specific processes (such as injection molding, stamping, casting, etc.). These accessories have precise sizes and shapes to meet the needs of different application scenarios. In the automotive industry, molded accessories can ensure the perfect fit between the various components of the vehicle; in the medical field, they must have extremely high precision to ensure the safety and reliability of medical devices.

Manufacturing Process

The manufacturing process for molded accessories typically involves several key steps: design, mold making, material selection, molding, and final quality inspection. Each step requires a high level of expertise and technical support.

Application Scenarios

Molded accessories are widely used for

(1) Plastic bottles, mobile phone cases, toys, etc.

(2) Door and window frames, drain pipes, etc. are all produced by extrusion molding.

Trends and Developments

CINCY Technology molded accessories are also constantly developing and improving. The emergence of new materials not only makes accessories more durable, but also allows for more complex designs.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Precision mold

- Equipment related to powder molding

- Clamp and auto parts machining

- Equipment related to molding choke

- Semiconductor packaging equipment

- Equipment related to new energy and lithium battery

- Medical devices/pharmaceutical equipment

- Equipment related to 3C industry

- Non-standard automatic equipment

- PVD coating center