Round tungsten steel rod mold

Round tungsten steel rod mold are made of carefully selected tungsten carbide materials and strictly adhere to the industry’s highest process standards. This tungsten carbide rod has become a key material in the field of high precision machining due to its excellent heat resistance, excellent impact resistance and wear resistance. It is widely used in the manufacture of various cutting tools such as end mills, reamers, drills, etc. It also provides solid support for precision tools such as countersink drills and engraving knives.

In mechanical applications, carbide rods serve as wear parts, ensuring stable operation and long service life of equipment with their excellent performance. We also offer custom-machined carbide rods to meet the specific needs of critical wear components in various machine applications. In addition to providing superior performance, these carbide rods are carefully designed and machined to ensure excellent performance in a variety of complex operating environments.

Carbide rods are available in standard lengths and diameters, as well as custom sizes. They are available unground, ground or ground and polished to ISO standard diameter tolerances or to customer drawings and specifications.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Precision mold

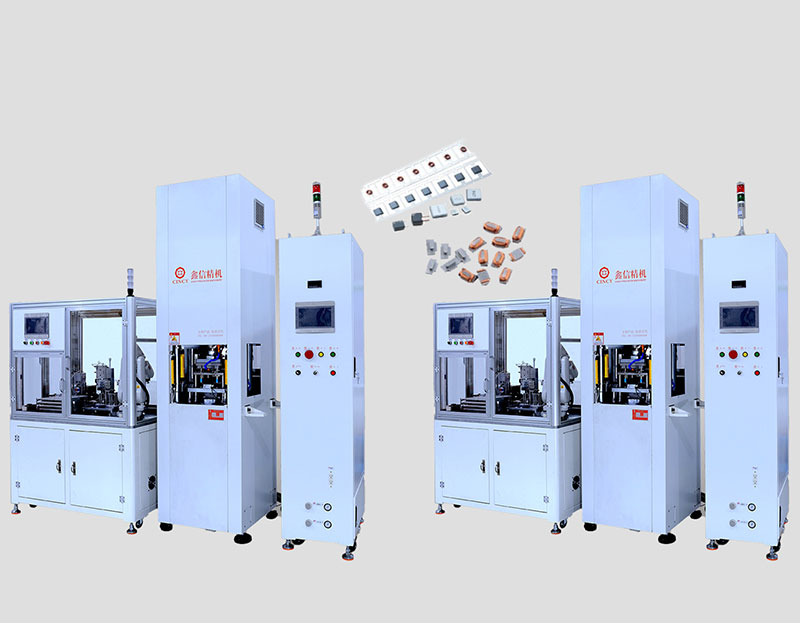

- Equipment related to powder molding

- Clamp and auto parts machining

- Equipment related to molding choke

- Semiconductor packaging equipment

- Equipment related to new energy and lithium battery

- Medical devices/pharmaceutical equipment

- Equipment related to 3C industry

- Non-standard automatic equipment

- PVD coating center