Precision ceramic products

Precision ceramics, the shining pearl of modern materials science, not only subverts the definition of traditional ceramics, but also demonstrates the superior performance of inorganic non-metallic materials. With its unique manufacturing process and tightly controlled ingredients, it produces high-precision products with mirror-like surfaces and extremely tight dimensional tolerances without the need for cumbersome mechanical grinding. The excellence of precision ceramics lies in their exceptional acid and alkali resistance, hardness and wear resistance, and excellent insulation properties. Compared with traditional ceramics, these indicators have made a qualitative leap, achieving improvements of several, dozens or even hundreds of times.

Within our company’s inventory, we are proud to have a comprehensive and diverse inventory of ceramic materials. These materials include not only traditional oxide ceramics, such as the proven alumina and zirconia, but also more advanced non-oxide ceramics, such as silicon carbide and boron nitride, with excellent performance. Our carefully selected and stocked ceramic materials are designed to meet the specific needs of precision ceramics in various industries and applications.

This wide range of materials demonstrates not only the strength of our company, but also our commitment to meeting our customers’ needs. Whether it is an application with specific requirements for high temperature resistance, wear resistance or specific chemical environments, we can provide suitable and high quality ceramic materials. Our goal is to ensure that every customer can find a solution to their unique needs in our library of ceramic materials.

CINCY offers a comprehensive service from development and design to application consulting. Our experienced team works closely with customers to provide guidance and support throughout the project lifecycle. From initial concept to final implementation, Precision Ceramics ensures that customers receive a customized solution that meets their specific requirements.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

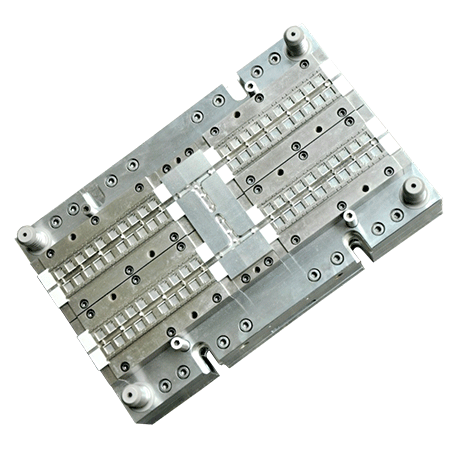

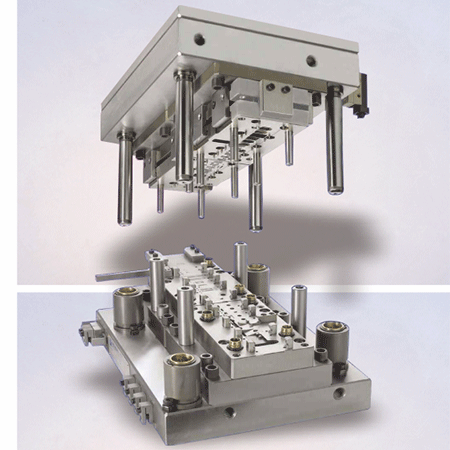

- Precision mold

- Equipment related to powder molding

- Clamp and auto parts machining

- Equipment related to molding choke

- Semiconductor packaging equipment

- Equipment related to new energy and lithium battery

- Medical devices/pharmaceutical equipment

- Equipment related to 3C industry

- Non-standard automatic equipment

- PVD coating center