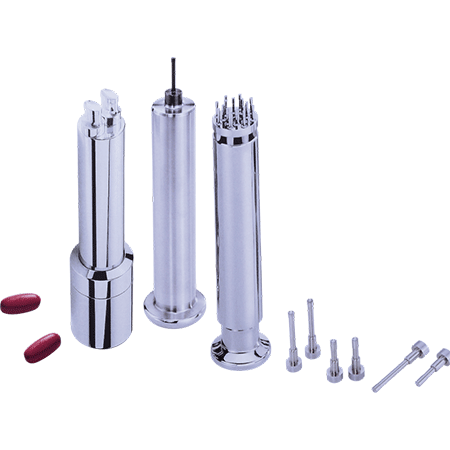

Precision ceramic dry press mold

In the fine craftsmanship of the ceramics industry, dry press molding technology plays a vital role. This is a body forming method that is carefully designed to convert powder into a body of specific shape and strength through precise control and manipulation.

We need to mix fine ceramic powder with a small amount of binder and use a specific granulation process to achieve ideal uniformity and fluidity of powder particles. These granulated powders are then placed in pre-designed metal molds, ready for the next step of molding.

During the molding stage, we use a high performance press to apply unidirectional pressure to the powder in the mold. The function of this pressure is not only to tightly compress the powder particles, but also to bind them tightly together through internal friction between the particles. During this process, the gas in the powder gap is gradually exhausted and the particles undergo an orderly displacement until they come close to each other and bite into each other, forming a green body that exactly matches the cross section of the mold.

Application Scenarios

Plastic products industry

Ceramic products industry

Rubber Products Industry

Construction materials industry

Pulp Molding Industry

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Precision mold

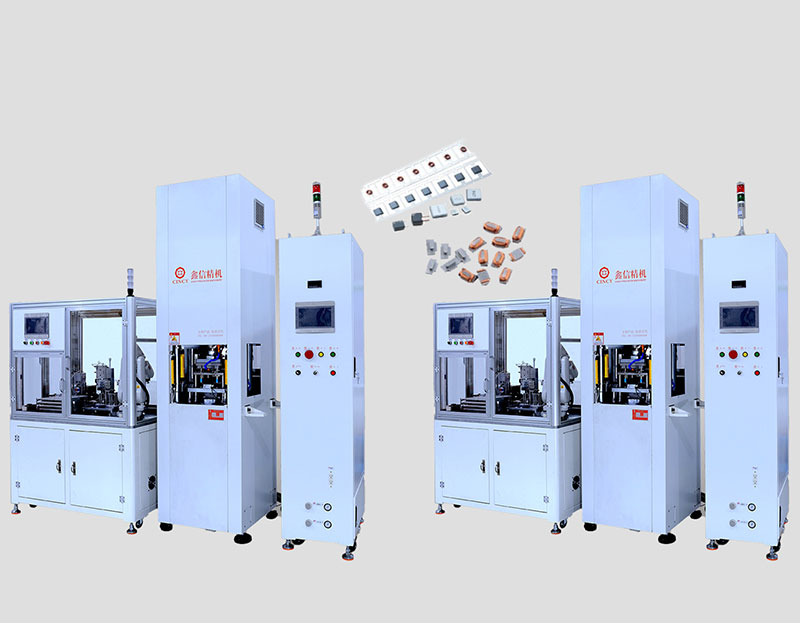

- Equipment related to powder molding

- Clamp and auto parts machining

- Equipment related to molding choke

- Semiconductor packaging equipment

- Equipment related to new energy and lithium battery

- Medical devices/pharmaceutical equipment

- Equipment related to 3C industry

- Non-standard automatic equipment

- PVD coating center