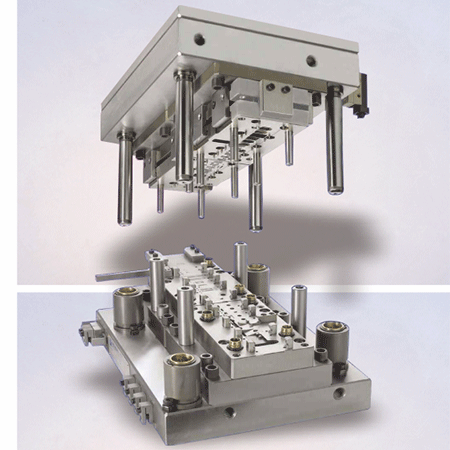

Powder metallurgy mold product

Powder metallurgy mold is a precision tool designed for powder metallurgy process, which plays an important role in the manufacturing process. Powder metallurgy technology is a technology that prepares parts and materials by pressing metal powder or non-metal powder into shape and undergoing processes such as sintering.

Product Features:

High precision: Using advanced processing technology and strict quality control process to ensure that the mold size is accurate and meet the requirements of various customers for details.

Long life: Selecting high quality steel as raw material and undergoing special heat treatment process greatly improves the hardness and wear resistance of the mold, thereby prolonging the service life.

Customized service: Provide personalized design solutions according to the specific needs of customers, whether simple or complex geometric shapes can be accurately realized.

Rapid delivery: With an efficient production management system and rich industry experience, it can shorten the delivery cycle while ensuring quality.

Environmentally friendly: Compared with traditional casting methods, powder metallurgy reduces material waste and energy consumption, which is more in line with the concept of sustainable development.

Application Range:

1. Automobile industry

2. Electrical and electronic

3. Tooling Industry

4. Medical equipment

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Precision mold

- Equipment related to powder molding

- Clamp and auto parts machining

- Equipment related to molding choke

- Semiconductor packaging equipment

- Equipment related to new energy and lithium battery

- Medical devices/pharmaceutical equipment

- Equipment related to 3C industry

- Non-standard automatic equipment

- PVD coating center