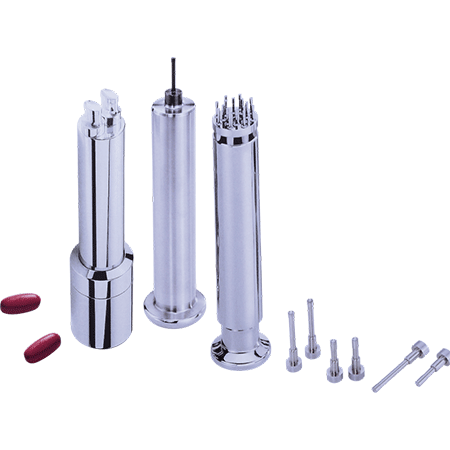

Pharmaceutical mold

Pharmaceutical molds are a key tool in the production of various pharmaceutical dosage forms. Its accuracy and quality directly affect the appearance, dosage accuracy and production efficiency of the drug.

Each pharmaceutical mold has been carefully designed by professional designers who fully consider many factors, such as the characteristics of the drug, dosage requirements, and the best way for the human body to absorb it.

In terms of material selection, pharmaceutical molds also have strict standards. High-quality steels, alloys and other materials are widely used in the production of molds. These materials not only have extremely high hardness and wear resistance, and can withstand long-term and high-intensity production tests, but also have good corrosion resistance and will not have any adverse reactions with the ingredients of the drug, thus ensuring the quality and safety of the drug.

Stability during the production process is also a highlight of pharmaceutical molds. With advanced manufacturing processes and precision machining technology, pharmaceutical molds can maintain stable performance on high-speed production lines. Whether in large batch production or small batch custom production, it can ensure that the size, shape and weight of each drug strictly meet the standards. This high degree of consistency is crucial for quality control of drugs and can give doctors and patients confidence in the effectiveness of drugs.

Pharmaceutical molds play an irreplaceable role in the pharmaceutical industry. With its professional design, stable performance, wide adaptability and convenient operation, it provides a solid guarantee for the production of drugs. In the future, with the continuous advancement of science and technology, we have reason to believe that pharmaceutical molds will continue to innovate and develop, making greater contributions to human health.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Precision mold

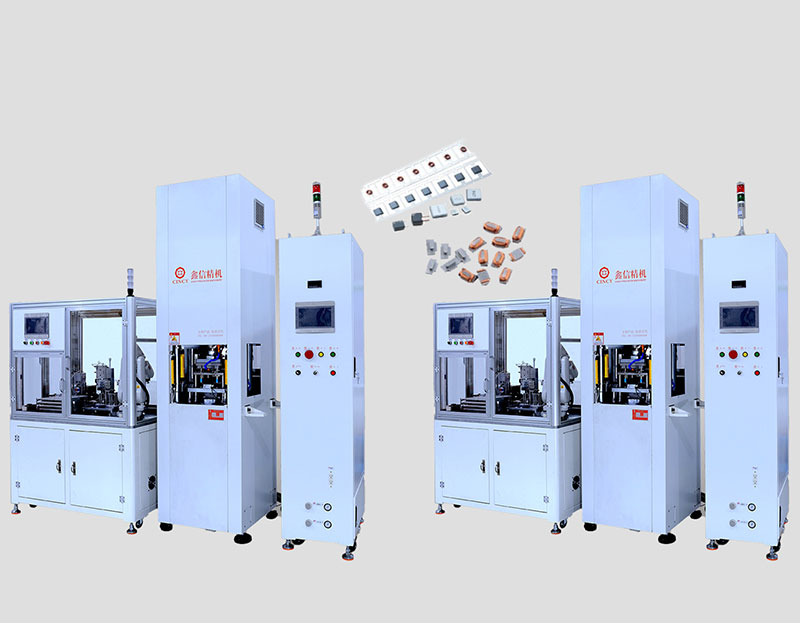

- Equipment related to powder molding

- Clamp and auto parts machining

- Equipment related to molding choke

- Semiconductor packaging equipment

- Equipment related to new energy and lithium battery

- Medical devices/pharmaceutical equipment

- Equipment related to 3C industry

- Non-standard automatic equipment

- PVD coating center