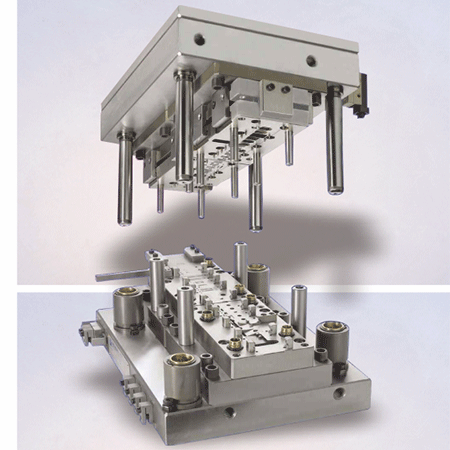

Lithium battery case mold

1. What is a lithium battery case mold?

Lithium battery case molds are specialized tools used to manufacture battery cases. By precisely controlling the shape and size of the metal material, they ensure that the final produced battery canister meets strict safety and performance standards. These molds are usually manufactured using high-precision machining technology to ensure that each battery case can accurately match the internal components of the battery and remain stable in various environments.

2. The Importance of Mold Design

1. Safety: The battery case is directly related to the overall safety of the battery. A well-designed mold can ensure that the shell has sufficient strength and sealing to prevent the battery’s internal chemicals from leaking or being exposed to external impacts.

2. Performance Optimization: The design of the housing also affects the heat dissipation performance of the battery. By carefully designing the shell, it can be ensured that the heat generated by the battery during operation is effectively dissipated, thereby improving the battery’s efficiency and extending its service life.

3. Cost Effectiveness: Efficient mold design can also reduce the scrap rate in the production process and reduce the overall manufacturing cost.

3. Technical trends in mold making

1. Digital manufacturing: Design and simulation using CAD/CAM software can greatly shorten the mold development cycle and improve its accuracy.

2. Automated manufacturing: Robots and automated production lines can achieve standardization and quality consistency in the mold manufacturing process, while significantly improving production efficiency.

3. Use of new materials: To further reduce battery weight and improve durability, new lightweight and high-strength alloys are gradually being used in shell mold manufacturing.

4. Sustainable development: With the continuous improvement of environmental protection requirements, more and more companies are beginning to explore recyclable materials and more energy-efficient production processes to reduce the impact on the environment.

With the continued growth of the electric vehicle market and technological advances, the demand for high-performance lithium batteries will continue to increase. This not only means that the requirements for the battery itself will become more stringent, but also that the requirements for the design and manufacture of battery case molds will become more stringent. CINCY Technology’s future molds will pay more attention to customization to meet the specific needs of various application scenarios.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Precision mold

- Equipment related to powder molding

- Clamp and auto parts machining

- Equipment related to molding choke

- Semiconductor packaging equipment

- Equipment related to new energy and lithium battery

- Medical devices/pharmaceutical equipment

- Equipment related to 3C industry

- Non-standard automatic equipment

- PVD coating center