Injection molding mold

What is an injection mold?

An injection mold is a mold used specifically for the injection molding process. It injects molten plastic into the mold under high pressure, waits for it to cool and solidify, and then opens the mold to remove the finished product. The process is simple: heat → inject → cool → open mold → remove. Each step is critical and determines the quality of the final product.

Injection Mold Design and Manufacturing

The mold manufacturing process is equally complex and delicate. Usually, steel with high hardness and wear resistance is selected as the main material to ensure the durability and stability of the mold. From rough machining to fine machining and surface treatment, each link must be strictly controlled to ensure that the precision of the mold reaches the micron level.

Use of injection molds

The application of injection molds is extremely wide. It covers almost all industries that use plastic products, such as automobile manufacturing, home appliances, medical devices, packaging materials, etc. With the continuous emergence of new materials and new technologies, injection molds are also constantly developing and changing to meet more diverse needs.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Precision mold

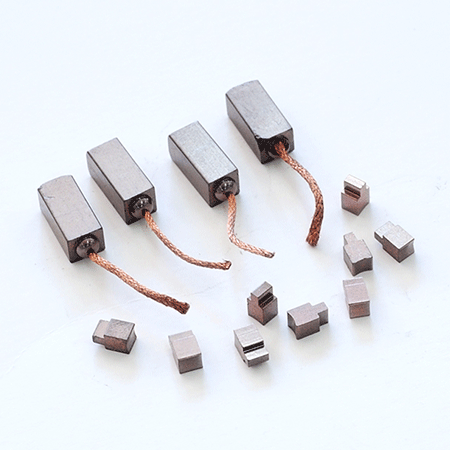

- Equipment related to powder molding

- Clamp and auto parts machining

- Equipment related to molding choke

- Semiconductor packaging equipment

- Equipment related to new energy and lithium battery

- Medical devices/pharmaceutical equipment

- Equipment related to 3C industry

- Non-standard automatic equipment

- PVD coating center