Injection Lithium battery mold factory

Our high precision lithium battery injection molds are designed to meet the quality and efficiency requirements of today’s rapidly growing battery market. Combining advanced manufacturing technology and strict quality control systems, we provide not only the mold itself, but also the total solution to help customers achieve more efficient production and higher quality products.

Features and Benefits:

Excellent design capabilities: Designed using 3D CAD software to ensure that every detail is carefully considered to meet the needs of different types of lithium batteries.

High quality materials: High-quality imported steel is used as the base material, and its hardness and wear resistance are enhanced by special treatment processes to ensure long-term stable operation.

Precision machining: High-end equipment such as CNC machine tools are introduced to complete the machining of all key parts to ensure that the mold size is accurate.

Surface treatment technology: Advanced surface treatment methods such as electroplating and polishing are used to improve the corrosion resistance and aesthetics of the mold.

Quick mold change system: The design is easy to change, which reduces production line downtime and improves work efficiency.

Comprehensive service support: From pre-consultation to post-maintenance, providing a one-stop service experience.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Precision mold

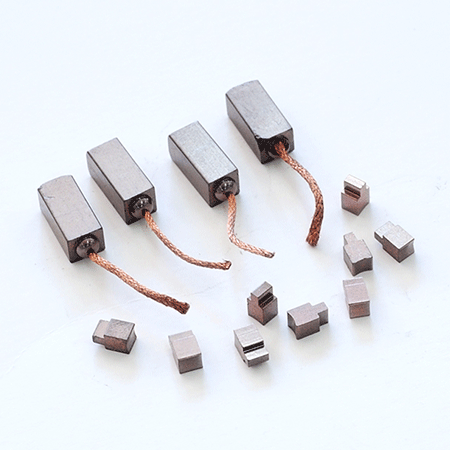

- Equipment related to powder molding

- Clamp and auto parts machining

- Equipment related to molding choke

- Semiconductor packaging equipment

- Equipment related to new energy and lithium battery

- Medical devices/pharmaceutical equipment

- Equipment related to 3C industry

- Non-standard automatic equipment

- PVD coating center