Carbon brush mold

Manufacturing Process

The application of precision machining technology is extremely critical in the carbon brush mold manufacturing process. Common manufacturing methods include computer numerical control (CNC) machining, electrical discharge machining (EDM), wire EDM, etc. These advanced manufacturing technologies can help achieve accurate replication of complex geometric shapes, while also improving the surface finish of the mold and reducing the need for post-processing.

Quality Control

To ensure the quality of the final product, CINCY Technology carries out strict quality control at every stage. From the inspection of raw materials to the testing of finished products, each step must be carried out according to strict standards. We use a three-dimensional coordinate measuring machine (CMM) to check the dimensional accuracy of the mold; we use a microscope to check the surface roughness; and we even simulate the actual working environment to test that the carbon brush can work properly under various conditions.

Field of Application

Carbon brushes produced by carbon brush molds are widely used in various fields, from home appliances to aerospace, almost everywhere. In the automobile industry, carbon brushes are used to start motors and generators; in wind power generation systems, carbon brushes are responsible for transmitting electrical energy from the rotating part to the fixed part.

CINCY Technology’s carbon brush molds are also constantly being developed and improved. Future trends may focus more on the use of environmentally friendly materials and the improvement of automation.

The FAQ is regularly updated to reflect the latest information and to ensure that you have the most accurate details at your fingertips.

Thank you for choosing us, and we hope you find the answers you need!

- Precision mold

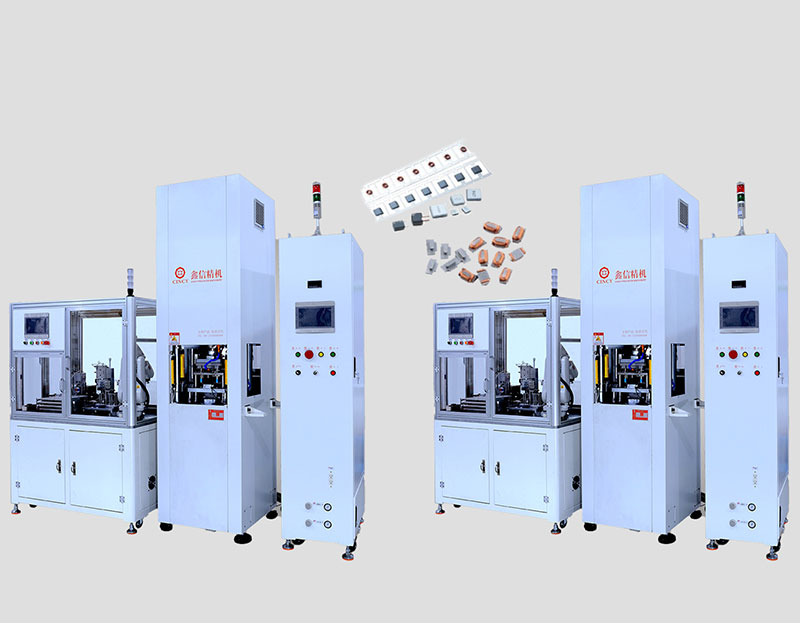

- Equipment related to powder molding

- Clamp and auto parts machining

- Equipment related to molding choke

- Semiconductor packaging equipment

- Equipment related to new energy and lithium battery

- Medical devices/pharmaceutical equipment

- Equipment related to 3C industry

- Non-standard automatic equipment

- PVD coating center