Semiconductor Packaging Equipment: Technical Features and Performance Comparison

2024-6-29 2:50:41

In the field of semiconductor manufacturing, packaging equipment is a key link to ensure stable and reliable chip performance and extend its service life. With the continuous advancement of technology, many semiconductor packaging equipment have appeared on the market, each with its own characteristics. This article will compare the technical features and performance of these equipment to help readers better understand and choose the right packaging equipment.

1. Comparison of Technical Features

Packaging accuracy: Packaging accuracy is one of the important indicators to measure the performance of packaging equipment. High-precision packaging equipment can ensure the precise alignment of the chip and the packaging substrate, reduce errors in the packaging process, and improve the reliability and stability of the product.

Packaging speed: With the expansion of production scale, packaging speed has become a key factor affecting production efficiency. High-speed packaging equipment can greatly improve production efficiency and reduce production costs while ensuring packaging quality.

Automation level: Modern packaging equipment pays more and more attention to improving automation. Highly automated packaging equipment can reduce manual intervention, reduce human error rate, and improve production efficiency and product quality.

Flexibility: With the continuous increase in the variety of semiconductor products, packaging equipment needs to have higher flexibility to adapt to the packaging needs of different products. Flexible packaging equipment can quickly adjust parameters and process flows to meet different production needs.

2. Performance Comparison

Stability: The stability of packaging equipment directly affects the quality and reliability of the product. Packaging equipment with stable performance can maintain stable performance output during long-term operation, reducing the failure rate and downtime.

Ease of use: A good user interface and ease of operation can reduce the difficulty of operation and improve the operation efficiency. Packaging equipment with strong ease of use can reduce operator training time and cost, and improve overall production efficiency.

Energy conservation and environmental protection: With the improvement of environmental awareness, energy saving and environmental protection have become important performance requirements for packaging equipment. Energy-saving and environmentally friendly packaging equipment can reduce energy consumption and emissions, and reduce the impact on the environment.

After-sales service: High-quality after-sales service can ensure that equipment problems are solved in a timely and effective manner. Good after-sales service can reduce the impact of equipment failure on production and improve customer satisfaction.

3. Conclusion

When selecting semiconductor packaging equipment, it is necessary to comprehensively consider the technical characteristics and performance of the equipment. Different equipment has differences in packaging accuracy, speed, automation level and flexibility. Users must select suitable equipment according to their own production needs. At the same time, the stability, ease of use, energy saving and environmental protection, and after-sales service of the equipment are also important factors to consider. Through comprehensive comparison and evaluation, users can choose semiconductor packaging equipment with superior performance and reliable quality, providing a strong guarantee for semiconductor manufacturing.

Latest News

- Powder moulding machine selection guide: how to choose the right equipment for your production needs

- There are many factors to consider when selecting a powder moulding machine to ensure that the equipment selected will meet production requirements. The followi...

- Dressing and forming equipment: a tool to ensure part accuracy and quality?

- Dressing and forming machines play a vital role in the manufacturing industry. Through a series of precise mechanical operations, they ensure that workpieces me...

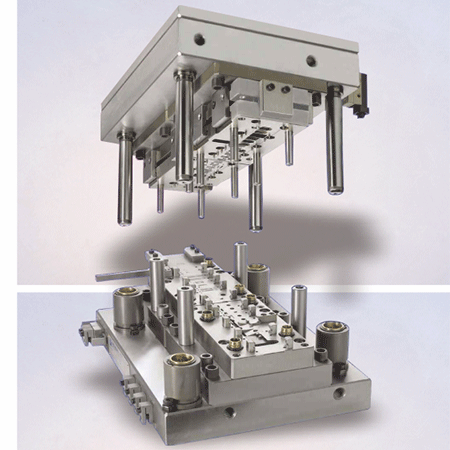

- Powder Metallurgy Mold: A Key Component in the Metal Forming Process

- Powder metallurgy dies are an essential key component in the metal forming process. They use powder metallurgy technology to press metal powder into shape and t...

- Vertical powder forming machine: an efficient and precise industrial manufacturing tool

- In the rapid development of modern manufacturing, vertical powder forming machine, as an advanced manufacturing process equipment, is playing an increasingly im...

- Powder metallurgy mold: the core of efficient metal forming process

- Powder metallurgy mold, as a key component in the metal forming process, is becoming an indispensable and important tool in the manufacturing industry with its ...