Precision Machining Unveiled: Crafting Excellence in Automotive Parts

2024-1-4 9:45:11

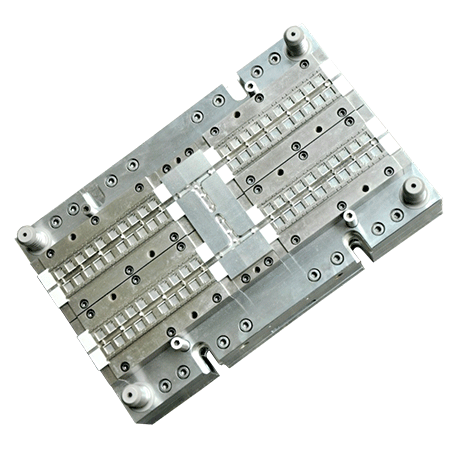

Precision machining in the automotive industry represents the pinnacle of manufacturing, ensuring the production of high-quality, reliable, and efficient auto parts. This process involves using advanced machinery to remove material from a workpiece to meet tight tolerances and specific design requirements.

Benefits:

Accuracy and Consistency: Precision machining ensures that each auto part is crafted with incredible accuracy and consistency, meeting the exact specifications required for optimal performance.

Versatility: This manufacturing method can be applied to a wide range of materials, from metals to plastics, providing flexibility in the production of various auto components.

Enhanced Efficiency: With the aid of computer numerical control (CNC) technology, precision machining significantly enhances the efficiency of the manufacturing process, allowing for faster production times and reduced waste.

Cost-Effective: While initial setup costs might be relatively high, the long-term cost-effectiveness of precision machining lies in its ability to produce high volumes of precise components with minimal waste.

Challenges:

High Initial Costs: Implementing precision machining in an automotive manufacturing facility can be capital-intensive, especially for smaller businesses.

Skilled Labor Requirements: Operating precision machinery demands skilled technicians who are adept at programming and overseeing the machining process, contributing to labor challenges.

Complex Programming: The programming required for CNC machines can be intricate, and errors in the programming stage may lead to costly mistakes during production.

Case Studies:

Aerospace Precision for Automotive Quality: The precision machining techniques used in the aerospace industry are increasingly finding applications in automotive manufacturing. This crossover highlights the reliability and quality achieved through precision machining.

Formula 1 Advancements: The automotive industry often draws inspiration from Formula 1 racing, where precision machining plays a vital role in creating high-performance auto parts. The precision required in these racing machines filters down to influence consumer vehicle technologies.

Conclusion:

Precision machining stands as a cornerstone in the automotive manufacturing landscape, offering unparalleled benefits in terms of accuracy, efficiency, and versatility. While challenges exist, advancements in technology and increased access to skilled labor are mitigating these obstacles. As seen in aerospace and high-performance racing, precision machining is not just a manufacturing method; it's a catalyst for innovation and excellence in the automotive world.

Latest News

- Cold heading dies: exquisite craftsmanship and excellent quality

- As an important tool in the field of metal processing, cold heading dies have always attracted much attention in the industry for their exquisite craftsmanship ...

- Semiconductor molds: the heart of precision manufacturing

- Semiconductor molds play a critical role in the semiconductor manufacturing industry, and their quality and precision are directly related to the performance an...

- What are the key features of the test packaging machine?

- As an instrument specially designed to test the performance of packaging materials or finished packages, the test packaging machine has many key features that e...

- Multifunctional magnetic core processing machine: a technological model of precision manufacturing

- Multifunctional magnetic core processing machine, as an important equipment in the field of modern magnetic material processing, has become an indispensable too...

- In-depth analysis of cold heading die manufacturing technology

- Cold heading die manufacturing is a key technology in the field of metal processing. It involves several links, such as die design, material selection, manufact...