Precision ceramic products

In our powder metallurgy, we prepare a powder mixture as raw material, and then use a four-beam and four-column hydraulic press with powder metallurgy. After the four-beam, four-column hydraulic press is combined with a powder metallurgy mold, we press and shape it, perform high-pressure molding, and then sinter it to form a finished product with the shape and size required by the mold used. .

The design of powder metallurgy molds must take into account many factors, including the characteristics of the powder material, the pressing method, the strength and wear resistance of the mold material, the shape and size of the product, and so on. In the design, it is necessary to follow some basic principles, such as giving full play to the process characteristics of less powder metallurgy, no cutting processing and near-shape forming to ensure that the blank achieves three points: geometric shape and size, accuracy and surface roughness, density and distribution. basic requirements.

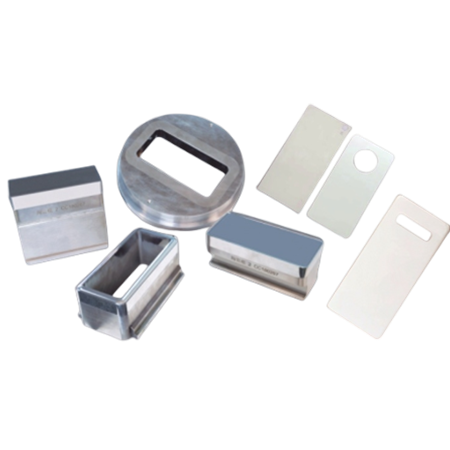

Our company has adequate technical experience on integrated mold. The mold products we developed include: Integrated mold SMD series1205,1004,0804,0603,0618,0612,0502,0512,0402,0412,0310,2520,2016,Specialized in SMD series mold for our customers, Inserted production of 0210 inductance all-in-one cold and hot pressing mold.