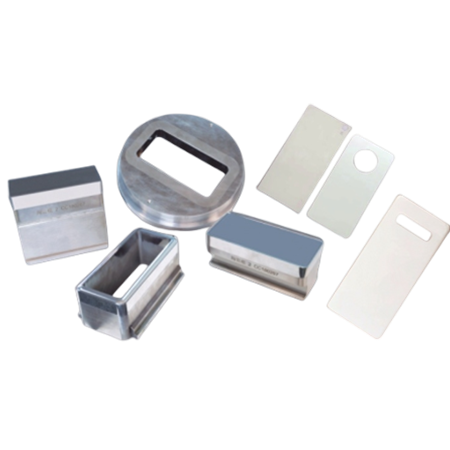

Precision ceramic dry pressing mold

Precision ceramic dry pressing mold is an important tool for manufacturing ceramic parts by dry pressing process. Dry pressing is a molding technique in which ceramic powder is pressed into a specific shape in a mold under high pressure.

Advantages

Manufactured using advanced processing technology with high precision, it can meet the manufacturing needs of high-precision ceramic parts;

Made of high-quality materials with high stiffness, which can ensure the stability and life of the mold;

Made of high-quality materials, it has a long service life and can ensure the stability and continuity of production;

It has high heat resistance, can work for a long time in high temperature environment, and is not easily deformed and damaged;

Die production equipment

5 German ZEISS three-dimensional coordinate measuring instruments, 2 Japanese Tokyo profilometers, 2 Japanese Tokyo roundness measuring instruments, 5 Japanese Nikon projectors, 2 TESA two-dimensional height gauges, 8 two-dimensional measuring instruments, and 1 Japanese Mitutoyo measuring instrument Precision and advanced testing equipment such as batches; 30 sets of Swiss Achi slow wire cutting machines (ICUTP5505 sets), 5 sets of Japanese Sodick oil cutting slow wire cutting machines (AP250L), 25 sets of Sodick cutting machines (AQ-400L, ALN400Gs) imported from Japan, 25 Japanese Sodick mirror spark machines, 10 Japanese Makino mirror spark machines, 5 optical grinders, 10 CNC form grinders, 5 coordinate grinders, 40 imported spark machines, High-speed machining, such as Japanese FANUC and YASDA 20 centers, 20 high-precision engraving machines, 30 ordinary lathes, 20 universal tool grinders, 20 internal and external cylindrical grinders, 50 surface grinders, 30 CNC controlled lathes, 30 ordinary lathes, and 18 sets of wires, 3 sets of fluid polishing machines and other high-precision advanced machining equipment.