Powder Metallurgy Molds: Innovations Shaping the Future of Manufacturing

2024-1-4 9:24:52

Powder metallurgy molds are at the forefront of transformative technologies, revolutionizing manufacturing across industries. This article delves into their evolution, applications, advantages, manufacturing intricacies, and the anticipated trends and challenges that will define their future.

Definition and Development History

Tracing the roots of powder metallurgy molds unveils a fascinating journey from early experimentation to the cutting-edge technologies that define them today. Understanding their historical development provides context to their present significance.

Application Fields and Advantages

Explore the myriad applications of powder metallurgy molds across industries. From automotive to aerospace, these molds offer unique advantages, showcasing their versatility and indispensability in modern manufacturing.

Manufacturing Process and Key Technologies

Unlock the complexities of crafting powder metallurgy molds. This section provides insights into the precision and advanced technologies involved in their manufacturing, shedding light on the intricacies of the process.

Future Trends and Challenges

As we peer into the future, anticipate the trends that will propel powder metallurgy molds into new realms of innovation. Simultaneously, acknowledge the challenges that may shape their trajectory, providing a holistic view of what lies ahead.

FAQs

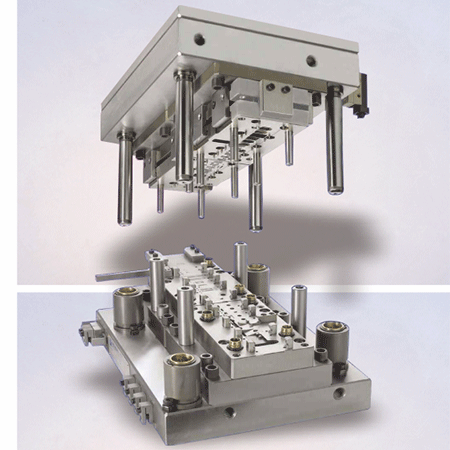

What is a powder metallurgy mold?

A powder metallurgy mold is a crucial component in the manufacturing process that involves shaping metal powders into complex and precise forms. It serves as the template or tool where the powder is compacted and then sintered to create a solid metal part with high precision.

In what fields are powder metallurgy molds widely used?

Powder metallurgy molds find extensive applications across various industries, including automotive, aerospace, medical, and more. They are utilized where intricate and precisely shaped metal components are required, such as in the production of automotive parts, medical implants, and aerospace components.

What are the key technologies in the manufacturing process of powder metallurgy molds?

The manufacturing process of powder metallurgy molds involves several key technologies. These include powder compaction, where metal powders are pressed into a desired shape within the mold, and sintering, a high-temperature process that fuses the metal particles, creating a solid and durable metal part.

What are the advantages of powder metallurgy molds?

Powder metallurgy molds offer numerous advantages. They allow for the production of complex and intricate metal parts with high precision. The process is cost-effective, minimizes material waste, and often results in parts with excellent strength and durability.

Conclusion

In conclusion, powder metallurgy molds stand as beacons of innovation, shaping the future of manufacturing. Whether you're a professional in the field or an enthusiast, understanding the intricacies of these molds is key to navigating the ever-evolving landscape of modern manufacturing.

Latest News

- Powder moulding machine selection guide: how to choose the right equipment for your production needs

- There are many factors to consider when selecting a powder moulding machine to ensure that the equipment selected will meet production requirements. The followi...

- Dressing and forming equipment: a tool to ensure part accuracy and quality?

- Dressing and forming machines play a vital role in the manufacturing industry. Through a series of precise mechanical operations, they ensure that workpieces me...

- Powder Metallurgy Mold: A Key Component in the Metal Forming Process

- Powder metallurgy dies are an essential key component in the metal forming process. They use powder metallurgy technology to press metal powder into shape and t...

- Vertical powder forming machine: an efficient and precise industrial manufacturing tool

- In the rapid development of modern manufacturing, vertical powder forming machine, as an advanced manufacturing process equipment, is playing an increasingly im...

- Powder metallurgy mold: the core of efficient metal forming process

- Powder metallurgy mold, as a key component in the metal forming process, is becoming an indispensable and important tool in the manufacturing industry with its ...