Plastic Packaging Equipment: Shaping the Green and Innovative Packaging of the Future

2024-11-5 8:09:16

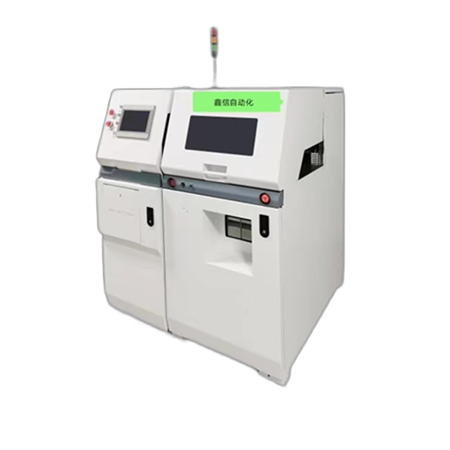

In today's rapidly developing packaging industry, plastic packaging equipment has become the first choice for many companies due to its high efficiency, flexibility and environmental protection. We understand that while striving for product quality and production efficiency, sustainability and environmental protection are equally important. Therefore, we focus on providing a series of advanced plastic packaging equipment to help customers shape the green and innovative path of future packaging.

1. The Key Advantages of Plastic Packaging Equipment

Efficient automation: Our plastic packaging equipment adopts advanced automation technology, which can greatly improve production efficiency, reduce manual intervention, and ensure product consistency and stability.

Environmental Protection and Energy Saving: We are aware of the importance of environmental protection. Therefore, all equipment meets strict environmental protection standards, adopts energy-saving design, reduces energy consumption and waste emissions, and helps enterprises achieve green production.

Diverse customization: To meet the needs of different customers, we provide diversified customization services for plastic packaging equipment, from material selection to packaging design, to meet customers' individual needs in all aspects.

Easy to maintain: Our equipment is simple and clear in design, easy to operate and maintain, which reduces enterprises' operating costs and improves equipment reliability and service life.

2. Wide application of plastic packaging equipment

Food packaging: In the food industry, our plastic packaging equipment can ensure the hygiene and safety of food, while providing a variety of packaging forms to meet the storage and transportation needs of different foods.

Pharmaceutical Packaging: In the pharmaceutical industry, we provide plastic packaging equipment that meets GMP standards to ensure that the packaging process of drugs is sterile and contamination-free, and to ensure the quality and safety of drugs.

Daily chemical packaging: In the daily chemical industry, our equipment can meet the packaging needs of various daily chemical products, from liquid to solid, from simple to complex, and provide perfect packaging solutions.

Other industries: In addition to the above industries, our plastic packaging equipment is also widely used in electronics, toys, automobiles and other fields, providing customers with a full range of packaging services.

3. Reasons to choose us

Professional team: We have a professional R&D team dedicated to technological innovation and product development, ensuring that our equipment always maintains a leading position in the industry.

Quality Service: We provide a full range of services from pre-sales consultation, installation and commissioning to after-sales service to ensure that customers receive the most timely and professional support during use.

Successful cases: We have established long-term cooperative relationships with many well-known companies, accumulated a wealth of successful cases, and provided customers with reliable and efficient packaging solutions.

In the future, we will continue to uphold the concept of "Innovation, Green and Efficiency" and dedicate ourselves to the research, development and manufacture of plastic packaging equipment to provide customers with higher quality, environmentally friendly and efficient packaging solutions. At the same time, we will also actively respond to national environmental protection policies, promote the sustainable development of plastic packaging, and jointly contribute to building a better future.

Latest News

- Powder moulding machine selection guide: how to choose the right equipment for your production needs

- There are many factors to consider when selecting a powder moulding machine to ensure that the equipment selected will meet production requirements. The followi...

- Dressing and forming equipment: a tool to ensure part accuracy and quality?

- Dressing and forming machines play a vital role in the manufacturing industry. Through a series of precise mechanical operations, they ensure that workpieces me...

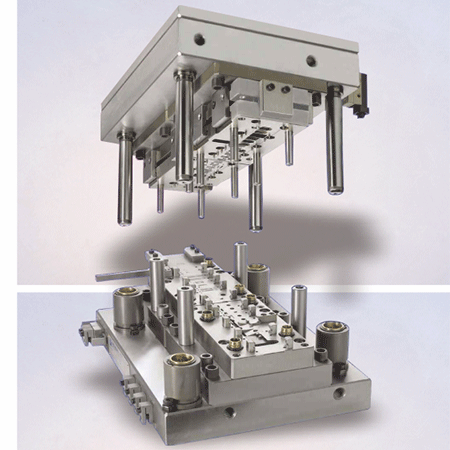

- Powder Metallurgy Mold: A Key Component in the Metal Forming Process

- Powder metallurgy dies are an essential key component in the metal forming process. They use powder metallurgy technology to press metal powder into shape and t...

- Vertical powder forming machine: an efficient and precise industrial manufacturing tool

- In the rapid development of modern manufacturing, vertical powder forming machine, as an advanced manufacturing process equipment, is playing an increasingly im...

- Powder metallurgy mold: the core of efficient metal forming process

- Powder metallurgy mold, as a key component in the metal forming process, is becoming an indispensable and important tool in the manufacturing industry with its ...