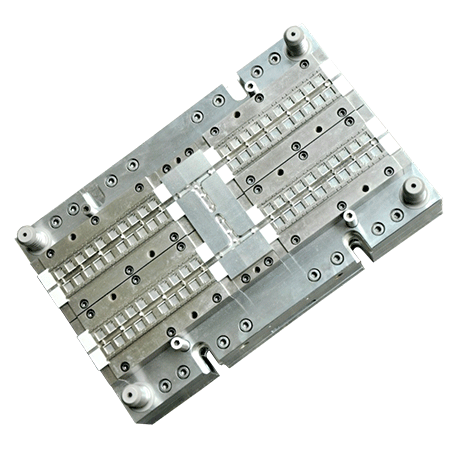

Multifunctional magnetic core processing machine: a technological model of precision manufacturing

2024-10-14 9:06:49

Multifunctional magnetic core processing machine, as an important equipment in the field of modern magnetic material processing, has become an indispensable tool in the process of magnetic core manufacturing with its high efficiency, precision and multifunctional characteristics. The following is a detailed analysis of multifunctional magnetic core processing machine, from the equipment structure to the working principle and then to the performance characteristics, to fully show you the charm of this technological product.

1. Equipment Structure

The structural design of the multifunctional magnetic core processing machine is exquisite, mainly including the following major parts:

Frame: As the supporting structure of the whole equipment, the frame is made of high-strength materials to ensure the stability and durability of the equipment.

Turntable mechanism: The turntable mechanism can be rotatably mounted on the frame to carry and transport multiple processing jigs to achieve continuous processing of magnetic cores.

Processing Jig: The processing jig is installed on the turntable mechanism to fix and support the magnetic core to ensure stability and precision during processing.

Lifting drive device: A lifting drive device is installed at the unloading station and the discharging station on the frame to realize automatic loading and unloading of magnetic cores.

Forming mechanism: The forming mechanism forms the magnetic core in the processing jig at the forming station to ensure that the size and shape of the magnetic core meet the requirements.

2. Operating Principle

The working principle of the multi-functional magnetic core processing machine is based on the rotation of the turntable mechanism and the coordinated operation of each processing station:

Rotary table rotation: The turntable mechanism rotates under the drive of the motor, driving each processing jig to circulate between the unloading station, the forming station and the discharging station.

Automatic loading and unloading: At the unloading station and the discharge station, the lifting drive device realizes automatic loading and unloading of the magnetic core, respectively, which improves the processing efficiency.

Forming: At the forming station, the forming mechanism performs precise forming on the magnetic core in the processing jig to ensure the quality and accuracy of the magnetic core.

3. Performance Features

The multifunctional magnetic core processing machine meets the various requirements in the magnetic core manufacturing process with its excellent performance characteristics:

High precision: Uses advanced processing technology and precise manufacturing technology to ensure that the size and shape accuracy of the magnetic core meet the requirements.

High efficiency: Through the rotation of the turntable mechanism and the coordinated work of each processing station, the continuous processing of the magnetic core is realized, which greatly improves the production efficiency.

Multifunctional: The equipment has multiple processing functions, such as cutting, forming, grinding, etc., which can be flexibly adjusted according to different processing requirements.

Stability: The frame and turntable mechanism are made of high-strength materials, which ensures the stability and durability of the equipment and reduces the failure rate.

Automation: The equipment is equipped with automatic loading and unloading devices and control systems, which realizes the automation and intelligence of magnetic core processing and reduces the labor intensity of operators.

In summary, the multifunctional magnetic core processing machine has become an indispensable tool in the magnetic core manufacturing process with its high efficiency, precision and multifunctional features. With advanced processing technology and precise manufacturing process, it ensures the quality and precision of the magnetic core, improves production efficiency, reduces costs, and makes important contributions to the development of magnetic material processing.

Latest News

- Cold heading dies: exquisite craftsmanship and excellent quality

- As an important tool in the field of metal processing, cold heading dies have always attracted much attention in the industry for their exquisite craftsmanship ...

- Semiconductor molds: the heart of precision manufacturing

- Semiconductor molds play a critical role in the semiconductor manufacturing industry, and their quality and precision are directly related to the performance an...

- What are the key features of the test packaging machine?

- As an instrument specially designed to test the performance of packaging materials or finished packages, the test packaging machine has many key features that e...

- In-depth analysis of cold heading die manufacturing technology

- Cold heading die manufacturing is a key technology in the field of metal processing. It involves several links, such as die design, material selection, manufact...

- Precision ceramic molding press to create perfect crafts

- Precision ceramic molding press, with its unique advantages, is becoming a key tool for creating perfect handicrafts. Through high-precision molding, complex st...