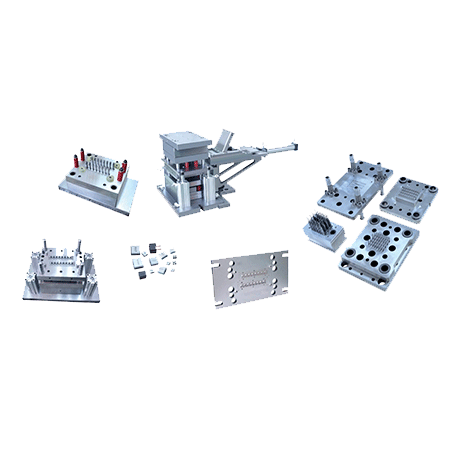

Molding choke product

A mold used to make inductors, also called an integrated inductor mold. Made of metallic materials with precise dimensions and construction to ensure inductor performance and consistency.

Operating Principle

The winding coil and magnetic core are tightly combined to form a complete integrated inductor. Precision manufacturing processes and mold design control parameters such as inductor geometry, size, and electrical performance.

Using processes such as high pressure injection molding or hot press molding, the coil and magnetic core materials are injected into the mold, and then the final inductor product is obtained through the cooling and demoulding process.

Advantage

High efficiency

Stable quality

Reduced costs

Easy to automate

Customizable

Application

Power Module

Portable mobile device

High-speed PC graphics cards and other areas

Medical instruments and industrial controls