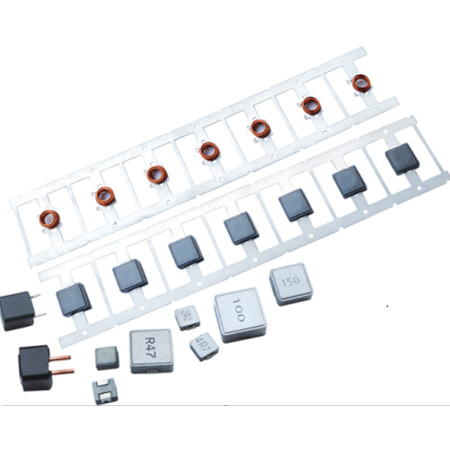

Molding choke press product

The mold choke press is the core equipment used to produce integrated molded inductors. This type of inductor consists of a base body and a winding body. The winding body is embedded in magnetic metal powder and pressed. Integrated inductors have higher inductance and lower leakage inductance than traditional inductors, and their SMD pins are the leads of the winding body and are directly formed on the surface of the base body.

Molding choke press life

The shelf life of a molding choke press is generally 6 months. If the equipment is operated in a harsh environment or is not used as required, its lifespan may be reduced accordingly.

|

|

|

|

Advantages of Molding Choke Press

Machines like ours are typically built using high-quality materials and components to withstand long periods of work and repeated use.

The designs of our one-piece inductor forming presses are usually very precise, with each component having its own specific function and role.

Many of our one-piece inductor forming presses are equipped with advanced maintenance and care systems that can automatically check various parts of the machine regularly and perform timely maintenance and upkeep.