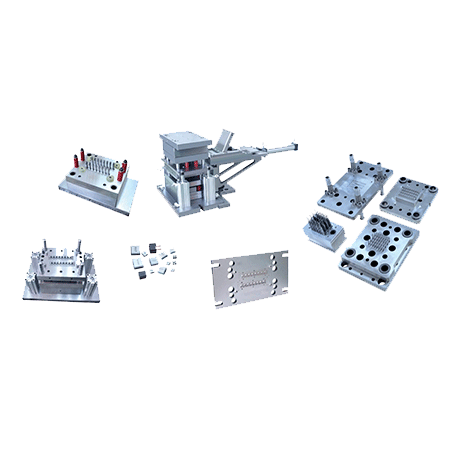

Molding choke mold Manufacturers

Molding choke mold is an important tool for manufacturing integrated molded inductors. Integrated inductors refer to inductor components made of composite profiles as the main material through one-time molding, injection molding and other processes.

This inductor component has many significant advantages, including a wide operating temperature range, low noise, strong resistance to vibration and impact, low magnetic leakage due to closed magnetic circuit structure design, strong anti-EMI ability, and the ability to achieve large-scale operation in a small size. current, power saving and other features.

The design and manufacture of molding choke molds need to take these characteristics and requirements into consideration. It must be able to precisely control the distribution and shaping of materials to ensure the performance and quality of inductive components.

|

|

|

|

Background technique

Inductor integrated molding has gradually emerged with the rapid development of science and technology and the continuous upgrading of electronic products. The emergence of integrated inductors, also known as power inductors, benefits from the development of computer motherboard technology and power supply technology. As the main frequency of CPUs continues to increase, the requirements for stable power supply and filtering have also increased accordingly. One-piece inductors just solve this problem.

The one-piece inductor is composed of metal powder, electrodes and coils. The coil body is embedded in the metal magnetic powder and is die-cast. The pins are the leads of the winding body and are directly formed on the surface of the base. This type of inductor has a stable structure and low impedance, resulting in higher efficiency. Its main functions include long-term operation under high current conditions, stable power supply for electronic devices such as CPUs, and filtering.

Troubleshooting and repair

1) When a customer encounters a mold failure, the after-sales service team will respond quickly to perform troubleshooting and repair work.

2) Provide on-site service or remote technical support, and provide effective solutions according to the fault situation to ensure that the customer's production is not affected.