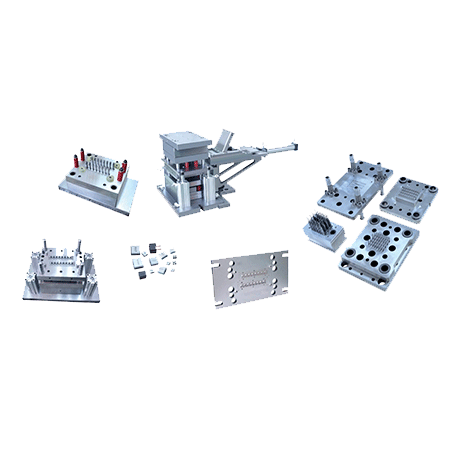

Molding choke mold factory

We are a professional factory focusing on Molding Choke mold manufacturing, with many years of experience in mold design and manufacturing. We are committed to providing customers with accurate, efficient and reliable mold solutions to meet the growing market demand for Molding Choke products.

Scope of use

car

aviation

communication

|

|

Routine maintenance

Keep it clean: Regularly clean the dust and dirt on the surface of the product to avoid dust accumulation that affects the heat dissipation effect. You can use a soft cloth or vacuum cleaner to gently remove dust. Be careful not to use cleaning tools with moisture to avoid damage to the product.

Temperature control: Pay attention to controlling the temperature of the environment where the product is located. Excessively high temperatures may cause product performance degradation or damage. Make sure the product is installed in a well-ventilated area away from direct sunlight or near heat sources.

Moisture-proof and moisture-proof: Products should avoid exposure to damp or high-humidity environments to prevent internal circuit components from getting wet, causing short circuits or corrosion. If the product accidentally comes into contact with water or other liquids, stop using it immediately and seek professional repair.

Avoid vibration and shock: The product should be placed in a stable location to avoid strong vibration and shock. Vibration and shock may cause the internal components of the product to become loose or damaged, affecting its normal operation.

Regular inspection: Regularly conduct performance inspections on products, including measurement of key parameters such as inductance value and resistance value. If performance abnormalities or deviations are found, professional maintenance personnel should be contacted promptly for maintenance.

How to ensure product performance?

Molding Choke products are manufactured using high-quality magnetic materials and precision processes to ensure stable working performance in high-current environments. At the same time, the products undergo strict testing and quality control to ensure that their electrical performance, physical performance and application performance meet industry standards and customer requirements.