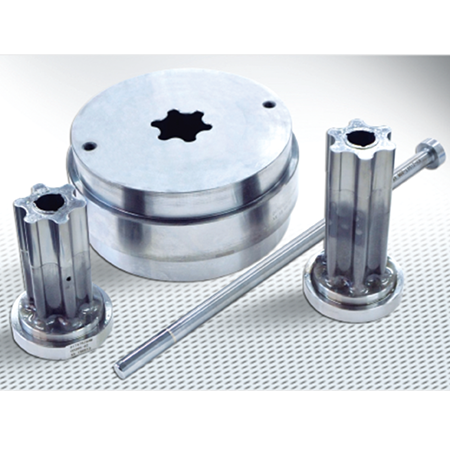

Metal Powder Mold Design

Metal powder mold is a special mold mainly used to produce metal powder parts or metal powder products. Its manufacturing materials and design take into account the properties of metal powders to more efficiently produce high-quality parts or products.

Mold design and manufacturing is an important link in industrial production. It involves controlling product shape, size and quality, and improving production efficiency. During the mold design process, our designers must fully understand product needs, process requirements and material properties, and use design software such as CAD to create accurate models. Mold design not only requires innovation, but also pays attention to practicality, feasibility and economy. To produce high-quality metal powder molds, high-precision machining equipment and process technologies such as CNC machining centers, EDM, wire EDM, etc. are required.

The company has introduced Swiss GF AgieCharmilles low speed wire cutter, Swiss GF Mikron high speed CNC machining center, Swiss GF AgieCharmilles electric discharge machine, Japanese YASDA CNC machining center, Japanese ROKU-ROKU high speed machining center, Japanese WAIDA jig grinder, Japanese AMADA optical projection grinder, Japanese OKAMOTO CNC shape grinder, original Sodick oil cutter imported from Japan, original Sodick low-speed wire cutter imported from Japan, Japanese Sodick mirror electric discharge machine, Japanese MAKINO electric discharge machine, the world's most advanced Swiss Pilates PVD coating equipment, and other advanced machining equipment. Precision quality inspection instruments include German ZEISS Trilinear Coordinate Measuring Instrument, Japanese ACCRETECH Contourgraph, Japanese ACCRETECH Roundness Tester, Japanese ACCRETECH Roundness Tester, Swiss TESA Height Gauge, Japanese Nikon Projector, and Austrian Alicona 3D Optical Measuring Instrument.