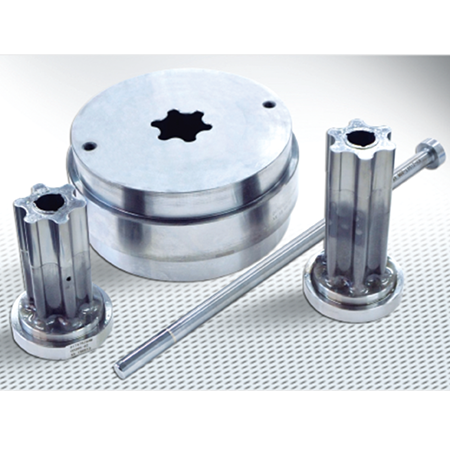

Metal Injection Mold product

Metal mold products are made of high-quality metal materials and undergo precision machining and heat treatment to ensure excellent durability. Compared with traditional plastic molds, metal molds can withstand higher pressure and temperature and are not easily deformed or damaged, which greatly extends their service life.

Metal molded products have high-precision molding capabilities and can produce parts with rich details and complex shapes. Due to the dimensional stability of the metal mold, the consistency of each injection molding can be ensured, greatly improving the quality and stability of the product.

Advantage

1) The molded products produced by metal molds have high precision and high consistency, and can meet the requirements of high-end industrial manufacturing.

2) The metal mold can minimize the segregation of alloy components, eliminate the unevenness of the casting structure, and improve the stability of the product.

3) Metal mold materials can be recycled and reused, meeting the requirements of sustainable development.

4) Products can be customized according to customers' requirements, to meet the needs of different customers.

5) Metal injection mold can be used in many industries, such as automobile, home appliance, electronics, communication and medical equipment.

Cases

Case 1: Automotive parts manufacturing

The automotive industry places extremely high demands on the precision and quality of parts. Metal powder molds play an important role in the production of automotive parts and can quickly form parts of various complex shapes, such as engine parts, brake pads, gas bottles, etc.

Case 2: Aerospace

The aerospace industry has extremely strict requirements for material performance and part accuracy. The application of metal powder molds in the aerospace field meets the requirements of high strength, light weight and precision. By using metal powder molds, high-performance aircraft parts and rocket engine parts can be produced, improving the safety and reliability of aerospace vehicles.

Case 3: Medical Device Manufacturing

Medical device manufacturing requires products with high precision, quality and reliability. Metal powder molds play a key role in the manufacture of medical devices, such as artificial joints, dental implants, surgical instruments, etc.

Case 4: Electronic Product Manufacturing

Electronic products require miniaturization, light weight and high integration. Metal powder molds are widely used in electronic product manufacturing to mold circuit boards, connectors, sensors and other parts. It can meet the requirements of high precision and miniaturization of electronic products.