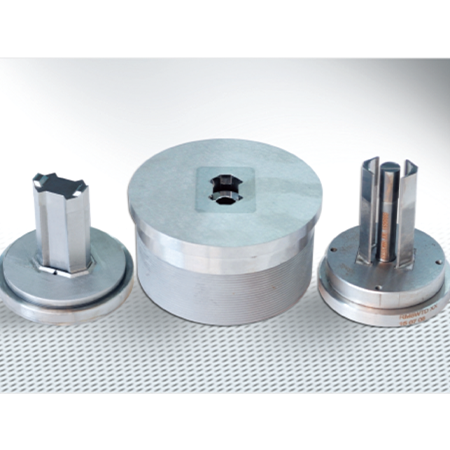

Magnetic Mold

Operating Principle

Magnetic molds usually consist of magnets, magnetic permeable plates and magnetic control devices. The magnetic field generated by the magnet interacts with the magnetic permeable plate, conducts the magnetic force to the mold, and generates a strong suction force to firmly hold the mold. The magnetic controller is responsible for controlling the opening and closing of the magnetic force.

During the injection molding process, the magnetic mold is first installed on the injection molding machine, and then the plastic mold to be injected is installed on the magnetic mold. The magnetic force is turned on by the magnetic control device. At this time, the magnetic attraction generated by the magnet firmly fixes the mold to the magnetic mold. When the injection molding machine starts working, the plastic material enters the cavity of the mold from the nozzle of the injection molding machine. Since the mold is firmly attached to the magnetic mold by the magnetic force, the injection unit of the injection molding machine can accurately inject plastic into the mold to form the desired product shape. After the injection molding process is completed, the magnetic control device turns off the magnet, and the product can be easily removed from the magnetic mold to complete the injection molding process.

CINCY typically uses a variety of magnetic materials and polymer combinations, including

Ferrite

NdFeB

Samarium Cobalt

Nylon 6

Nylon 12

PPS

The hygroscopicity, physical strength, magnetism, and even the maximum operating temperature of the product are affected by choosing the right combination.

Injection molded magnets can range from very simple shapes to very complex shapes. Depending on the magnetic material, the part may need to be magnetically oriented during the molding process to optimize magnetic properties.

Advantages

1) The magnetic field can penetrate materials of a certain thickness, allowing complex shapes and structures to be processed.

2) Magnetic mold processing does not require heating and cooling, and the processing time is short, which can improve production efficiency and reduce production costs.

3) No harmful substances are produced during the processing of our products, so they are environmentally friendly.

4) The magnetic field distribution of magnetic mold is uniform and stable, ensuring processing accuracy and stability.

Application

Automobile manufacturing

Electronic manufacturing

Hardware manufacturing