In-depth analysis of cold heading die manufacturing technology

2024-9-30 8:04:15

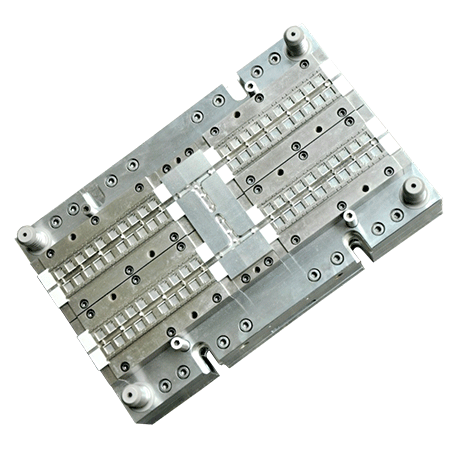

Cold heading die manufacturing is a key technology in the field of metal processing. It involves several links, such as die design, material selection, manufacturing process and quality control. The following is a four-point in-depth analysis of cold heading die manufacturing technology:

1. Die design:

The design of cold heading die is the most important link in the manufacturing process, and its design quality directly affects the service life of the die and the molding quality of the product. During the design process, factors such as the flow characteristics of the material, the size and distribution of the molding force, the strength and rigidity of the die must be fully considered. Through precise computer-aided design (CAD) and computer-aided engineering (CAE) analysis, the die structure can be optimized, stress concentration can be reduced, and the durability and molding accuracy of the die can be improved.

2. Material selection:

The material selection of the cold heading die is crucial, which determines the key properties of the die such as hardness, wear resistance, impact resistance and thermal stability. Commonly used die materials include high-carbon steel, alloy steel, cemented carbide and ceramic. When selecting materials, factors such as the operating conditions, cost budget and machining difficulty of the die must be fully considered. For example, hard alloy or ceramic materials with high hardness and good wear resistance should be selected for high-load and high-wear molds.

3. Manufacturing Process:

The manufacturing process of cold heading dies includes forging, heat treatment, machining and surface treatment. Forging can improve the density and mechanical properties of the material; heat treatment can make the mold achieve the required hardness and toughness through processes such as quenching and tempering; machining is used to accurately process the cavity and guide part of the mold; surface treatment such as carburizing and nitriding can further improve the wear resistance and corrosion resistance of the mold. Each step of the manufacturing process must be strictly controlled to ensure the quality and performance of the mold.

4. Quality Control:

Quality control is an important link in the manufacturing process of cold heading dies. Through rigorous inspection and testing, problems in the manufacturing process can be detected and corrected in time to ensure that the quality of the mold meets the design requirements. Common quality control methods include non-destructive testing (such as ultrasonic testing, magnetic particle testing, etc.), dimensional measurement, hardness testing, and fatigue testing. In addition, establishing a sound quality management system and monitoring the manufacturing process throughout the process is also an effective way to improve mold quality.

In summary, cold heading die manufacturing technology involves several links, and each link must be strictly controlled to ensure the quality and performance of the die. With the advancement of science and technology and the development of the manufacturing industry, cold heading die manufacturing technology will continue to innovate and improve, providing more efficient and precise solutions for the metal processing industry.

Latest News

- Cold heading dies: exquisite craftsmanship and excellent quality

- As an important tool in the field of metal processing, cold heading dies have always attracted much attention in the industry for their exquisite craftsmanship ...

- Semiconductor molds: the heart of precision manufacturing

- Semiconductor molds play a critical role in the semiconductor manufacturing industry, and their quality and precision are directly related to the performance an...

- What are the key features of the test packaging machine?

- As an instrument specially designed to test the performance of packaging materials or finished packages, the test packaging machine has many key features that e...

- Multifunctional magnetic core processing machine: a technological model of precision manufacturing

- Multifunctional magnetic core processing machine, as an important equipment in the field of modern magnetic material processing, has become an indispensable too...

- Precision ceramic molding press to create perfect crafts

- Precision ceramic molding press, with its unique advantages, is becoming a key tool for creating perfect handicrafts. Through high-precision molding, complex st...