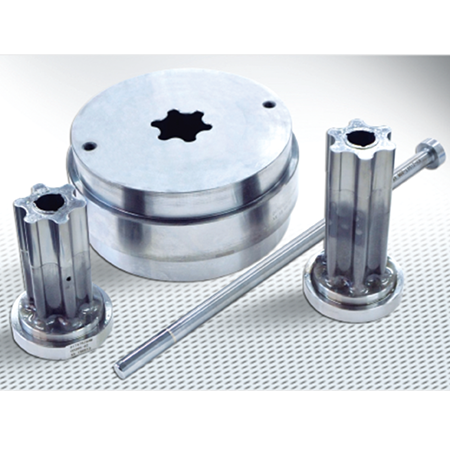

High precision Powder metallurgy mold

High-precision powder metallurgy molds are special molds mainly used to contain and shape solid metal powder into specific parts or products. This type of mold is very important for industrial production, especially when manufacturing small, complex parts, such as automotive parts, electronic products, etc. The advantages of powder metallurgy molds are that they have no special requirements for the mold, low molding pressure, simple mold structure, and general requirements for accuracy and surface roughness.

Manufacturing Process

The manufacturing process of powder metallurgy molds mainly includes the steps of powder preparation, mold design, compression molding and sintering. In the powder preparation stage, raw materials must be finely ground into micron-sized powder. In the mold design stage, the structure, size and accuracy requirements of the mold must be fully considered. In the compression molding stage, the powder is loaded into a mold and compacted under high pressure into a green body with a specific shape and density. Finally, the green body is densified by a sintering process, and a material with high strength and wear resistance is obtained.

Advantage

Our powder metallurgy molds use high-strength mold steel to ensure that they are solid, durable and not easily deformed during use. Through precision computer design and CNC milling, the mold surface is smooth and highly precise, allowing the molded metal parts to have high density and precise shapes.

Due to their high precision and quality, our powder metal molds are widely used in many industries such as automobile, motorcycle, electronics, etc.

We offer customized powder metal mold services and provide the most suitable mold design solutions and technical support based on customers' specific needs and product characteristics to ensure that each project can achieve the best results.

In the future, our high precision powder metallurgy mold manufacturing technology will develop in the direction of intelligence, green and precision. By introducing advanced intelligent manufacturing technology, the mold design and manufacturing process can be digitized and intelligent, and production efficiency and product quality can be improved.