Exploring Lithium Battery Molds: Crafting the Perfect Shape for Reliable Energy Storage

2023-12-26 8:56:57

The Significance and Functions of Lithium Battery Molds

Lithium battery molds play a pivotal role in shaping the landscape of sustainable energy storage. This section delves into their importance and multifaceted functions in ensuring the reliability and performance of lithium batteries.

Key Factors in the Design and Manufacture of Lithium Battery Molds

Unraveling the intricate process, this part explores the crucial elements involved in the design and manufacturing of lithium battery molds. From material selection to structural optimization, each factor influences the quality and efficiency of the molds.

Innovative Approaches to Enhancing Lithium Battery Mold Technology

Discovering the frontier of progress, this section investigates innovative methods to advance lithium battery mold technology. It explores how cutting-edge materials, intelligent manufacturing techniques, and optimized structural designs contribute to the evolution of these molds.

Frequently Asked Questions: Addressing Queries About Lithium Battery Molds

Responding to common inquiries, this part provides comprehensive answers to questions surrounding lithium battery molds. It covers aspects such as their impact on battery performance, key considerations in design and manufacturing, innovative techniques for improvement, the manufacturing process, and ensuring reliability and durability.

Frequently Asked Questions List:

-

- How does the Lithium battery mold impact battery performance and lifespan?

- What are the key factors to consider in designing and manufacturing high-quality Lithium battery molds?

- What innovative methods can improve the technology of Lithium battery molds?

- What is the manufacturing process for Lithium battery molds?

- How to ensure the reliability and durability of Lithium battery molds?

The Significance and Functions of Lithium Battery Molds

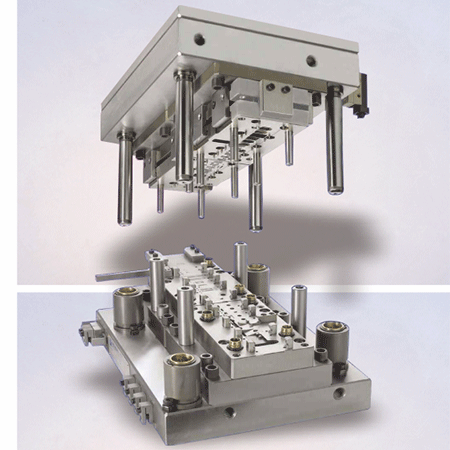

Lithium battery molds serve as the backbone of sustainable energy storage, intricately influencing the performance and longevity of lithium batteries. Far more than mere casings, these molds safeguard the core components, maintain internal structural consistency, and shield against external damage. Precise mold design and manufacturing ensure the uniformity of battery shapes, reducing material waste and enhancing energy density and efficiency. Simultaneously, adherence to strict safety standards is imperative to guarantee the reliability and durability of Lithium battery molds.

Key Factors in the Design and Manufacture of Lithium Battery Molds

Designing high-quality Lithium battery molds involves a meticulous consideration of various factors. Material durability, thermal conductivity, and lightweight characteristics are pivotal. The structural design directly influences the internal layout and overall efficiency of the battery. Therefore, a rational approach to design, coupled with fine control over manufacturing processes, ensures that each mold possesses consistent quality and performance.

Innovative Approaches to Enhancing Lithium Battery Mold Technology

In the pursuit of progress, innovative methods are at the forefront of advancing Lithium battery mold technology. The integration of advanced materials, such as composite materials or alloys with unique properties, enhances mold strength and thermal conductivity, thereby improving overall battery performance. Additionally, the incorporation of smart manufacturing technologies and optimized structural designs contributes to the ongoing evolution of Lithium battery molds.

Frequently Asked Questions: Addressing Queries About Lithium Battery Molds

How does the Lithium battery mold impact battery performance and lifespan?

The Lithium battery mold significantly influences performance and lifespan by protecting the core components, maintaining structural integrity, and preventing external damage. Uniform mold design ensures consistent battery shapes, reducing material waste and enhancing energy density.

What are the key factors to consider in designing and manufacturing high-quality Lithium battery molds?

Designing high-quality molds requires considerations such as material durability, thermal conductivity, and lightweight characteristics. Structural design is critical for internal layout and overall efficiency.

What innovative methods can improve the technology of Lithium battery molds?

Innovation involves using advanced materials like composites or special alloys, smart manufacturing technologies, and optimized structural designs to enhance mold strength and improve overall battery performance.

Lithium battery molds' manufacturing process is how?

The manufacturing process involves material selection, mold design, and precise control of manufacturing processes to ensure each mold's consistent quality and performance.

How to ensure the reliability and durability of Lithium battery molds?

Reliability and durability are ensured through strict quality control, including material quality checks, monitoring the manufacturing process, and final product inspections. Adherence to industry standards and safety regulations is also crucial.

This segmented content structure aims to provide a comprehensive exploration of Lithium battery molds, covering their importance, design and manufacturing processes, innovative improvements, and addressing common questions to enhance understanding in the field.

Latest News

- Powder moulding machine selection guide: how to choose the right equipment for your production needs

- There are many factors to consider when selecting a powder moulding machine to ensure that the equipment selected will meet production requirements. The followi...

- Dressing and forming equipment: a tool to ensure part accuracy and quality?

- Dressing and forming machines play a vital role in the manufacturing industry. Through a series of precise mechanical operations, they ensure that workpieces me...

- Powder Metallurgy Mold: A Key Component in the Metal Forming Process

- Powder metallurgy dies are an essential key component in the metal forming process. They use powder metallurgy technology to press metal powder into shape and t...

- Vertical powder forming machine: an efficient and precise industrial manufacturing tool

- In the rapid development of modern manufacturing, vertical powder forming machine, as an advanced manufacturing process equipment, is playing an increasingly im...

- Powder metallurgy mold: the core of efficient metal forming process

- Powder metallurgy mold, as a key component in the metal forming process, is becoming an indispensable and important tool in the manufacturing industry with its ...