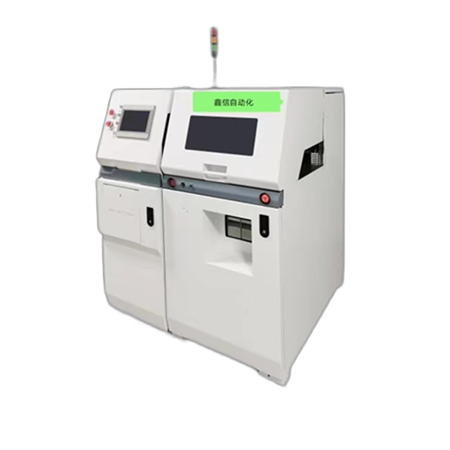

CNC powder forming machine: a model of manufacturing innovation and technological progress

2024-12-25 7:25:14

In the wave of modern manufacturing, CNC powder forming machine has gradually become a key equipment in many industries with its high precision, high efficiency and high stability. This technology has not only promoted the rapid development of powder metallurgy, cemented carbide, magnetic materials, fine ceramics and other fields, but also led the manufacturing industry to move towards intelligence and precision.

1. CNC powder forming machine: definition and working principle

CNC powder forming machine is a new type of hydraulic special equipment. It uses advanced mechanical, electrical, hydraulic, gas and instrument integrated control technology to press powdered materials into shape through precise program control. This process usually includes three main steps: feeding, pressing and demolding. The feeding system ensures that the powder material enters the mold evenly and continuously; the pressing system applies a certain amount of pressure and time to make the powder plastically deform in the mold to form a product with a specific shape, size and density; the demolding system is responsible for smoothly removing the molded product from the mold.

2. Technical advantages and application areas

The core advantage of CNC powder forming machine lies in its high precision and flexibility. Through flexible settings on the touch screen, the requirements for pressing and forming of complex-shaped and multi-variety step parts in the powder metallurgy industry can be met without changing the internal program. This feature makes CNC powder forming machines widely used in the forming of powder materials such as cemented carbide, electronic ceramics, inductor cores, T-Core inductors, magnetic materials, iron silicon aluminum, glass, and alloys. Especially in the powder forming of ultra-small, special-shaped parts, complex, multi-step and other precision products, CNC powder forming machines have shown incomparable advantages.

3. Intelligence and green manufacturing

With the continuous advancement of science and technology and changes in market demand, the technology of CNC powder forming machines is also constantly updated and developed. Intelligence is an important trend in the current development of CNC powder forming machines. By integrating advanced machine learning algorithms and big data analysis technologies, the equipment can achieve self-optimization, adjust the forming parameters according to real-time data, and ensure product quality. At the same time, the combination with the industrial Internet enables the equipment to be remotely monitored and maintained, which improves the flexibility and response speed of production.

In terms of green manufacturing, CNC powder forming machines also show their environmental protection and energy-saving characteristics. Use new environmentally friendly materials and processes to reduce pollution during the production process. By optimizing energy use, reducing energy consumption, and achieving green production. This is not only in line with the current global environmental protection trend, but also brings long-term benefits of sustainable development to enterprises.

4. Future Outlook

Looking to the future, CNC powder forming machines will make significant progress in technological innovation, application field expansion, global market competition, and safety and maintainability improvement. With the diversification and personalization of consumer demand, CNC powder forming machines will pay more attention to customized services. Through flexible production processes and modular design, they can quickly respond to market changes and provide customized solutions for different industries. At the same time, cross-industry technology integration will bring new application scenarios for CNC powder forming machines, such as special needs in biomedicine, aerospace and other fields will promote the further development of this technology.

In the context of globalization, the market competition for CNC powder forming machines is becoming increasingly fierce. Enterprises need to continue to innovate, strengthen R&D investment, and improve their technical level to maintain competitiveness in the global market. At the same time, seeking international cooperation and sharing resources and technologies are also important ways to accelerate the development of CNC powder forming machine technology.

As an important equipment in the manufacturing industry, the development trend of CNC powder forming machines marks the direction of progress for the entire industry. The in-depth integration of technological innovation and intelligence will bring higher precision, efficiency and environmental protection to CNC powder forming machines. The expansion of customized services and cross-border integration will further broaden its application areas. Under the background of global competition and cooperation, the future of CNC powder forming machines is full of infinite possibilities and worth looking forward to.

Latest News

- Injection molds: shaping the precision beauty of modern industry

- In the grand picture of modern industrial manufacturing, injection molds have become an indispensable core element with their unique craftsmanship charm and wid...

- Analysis of powder pressing technology: the key to improving product quality and production efficiency

- Powder pressing technology is an important material forming method, widely used in many fields such as automobiles, aerospace, and medical equipment. The follow...

- Powder moulding machine selection guide: how to choose the right equipment for your production needs

- There are many factors to consider when selecting a powder moulding machine to ensure that the equipment selected will meet production requirements. The followi...

- Dressing and forming equipment: a tool to ensure part accuracy and quality?

- Dressing and forming machines play a vital role in the manufacturing industry. Through a series of precise mechanical operations, they ensure that workpieces me...

- What is a Forming Compression Press?

- As an important piece of mechanical equipment, the forging press plays a key role in industrial manufacturing. However, many people do not know much about its w...