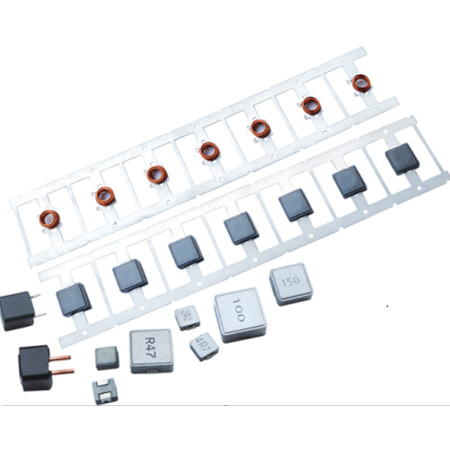

China Molding choke press product

The molding choke press uses advanced servo-hydraulic powder molding technology, which has the characteristics of high-precision pressing, high-efficiency production, and high stability. The equipment adopts a single-station design, making it easy to load and unload the mold, with high molding efficiency and safe and reliable operation. At the same time, the equipment adopts servo-hydraulic transmission, proportional pressure, flow control, speed, and pressure step-less adjustment. It can realize rapid lowering of mold closing, low pressure and slow speed mold protection, etc. It has the advantages of low noise and high precision.

|

|

|

Features

Our Molding choke press uses advanced control systems and precision mechanical structures to ensure precision and stability during the pressing process.

Our equipment has fast pressing and demoulding functions, which can quickly complete the pressing task and improve production efficiency.

Our one-piece inductor forming presses are manufactured using high-quality materials and components for outstanding stability and durability.

Our equipment is suitable for producing various specifications and types of integrated inductors, including inductor products of different sizes, shapes and materials.

Why Choose Us Molding Choke Press

When you choose our Molding Choke Press, you get excellent performance, efficient production, intelligent control, strong durability, user-friendly maintenance and professional technical support.