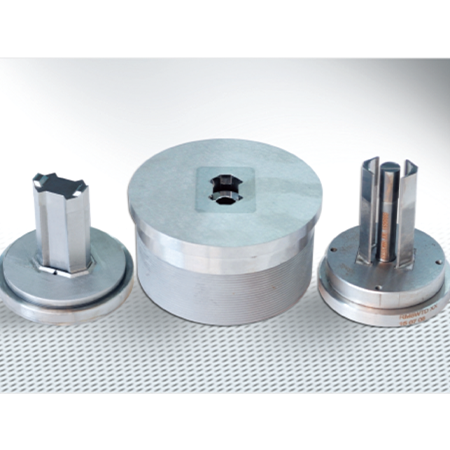

China Magnetic material mold

Magnetic material mold is an important part of modern industry. This type of mold has the characteristics of high strength, high hardness, wear resistance, corrosion resistance, etc., and is widely used in many fields.

|

|

|

Features and Benefits

The precision of our magnetic material molds can reach sub-micron level, which can meet the precision processing needs of tiny parts. This is due to the good magnetic permeability, permeability, dielectric constant and other characteristics of magnetic materials, which allows the mold to be processed and ground with high precision during the manufacturing process.

Our type of mold has the advantage of high-efficiency processing, which can greatly shorten the manufacturing cycle and reduce manufacturing costs, which is of great significance to the company's production efficiency improvement and cost control.

Manufacturing process and technological innovation

When making magnetic material molds, for example, the process flow of making sintered NdFeB blanks includes ingredients, smelting, powdering, powder orientation and shaping, sintering and other steps.

According to the orientation field requirements, the side plates and lining plates of the mold will be made of different materials. For example, the side plates will be made of wear-resistant magnetic conductive materials, while the lining plates will be made of wear-resistant non-magnetic conductive materials to produce a magnetization effect and improve Orientation magnetic field in the mold cavity.