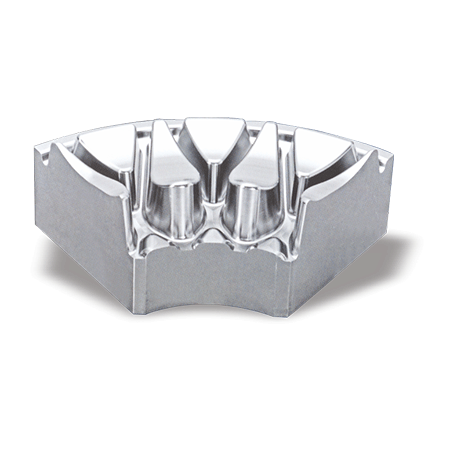

China Cold heading mold factory

The high performance cold heading tool is an advanced tool that combines high strength, high precision, high efficiency, long service life and easy maintenance. The product uses the latest generation of high-strength materials and precision manufacturing technology to ensure excellent stability and durability under high pressure and high load. We believe that high performance cold heading dies will become your right assistant in the metal processing process.

|

|

Product Advantages

High working efficiency

High product precision

Long life

Easy to maintain, reducing operating costs

widely used

The following points should be considered when using the product

Good lubrication is the key to reducing mold wear and extending tool life. During the cold heading process, make sure the mold is fully lubricated to reduce friction and heat generation.

Clean the mold surface regularly to remove dirt, oil, and metal debris. When cleaning, use a soft cloth or brush to avoid using hard objects that may scratch the mold surface.

Regularly check the wear of the mold, including the cutting edge, cavity, guide column and other parts. If serious wear or damage is found, it should be repaired or replaced in a timely manner.

According to product requirements and mold usage, adjust mold clearance, pressure and other parameters in a timely manner to ensure product quality and production efficiency.

During the storage and use of the mold, effective protective measures should be taken to avoid collision, rust and corrosion of the mold.

If the mold is damaged or worn, it should be repaired in time.