Blanking and Demoulding Machine Operation Skills and Safety Precautions

2024-6-21 7:49:52

Blanking and demoulding machines play an important role in the manufacturing industry, especially in the process of molding materials such as plastics and rubber. Correct operation can not only improve production efficiency, but also ensure the safety of operators. In the following, we will introduce the operation skills and safety precautions of molding machines in detail.

1. Operation Skills

Be familiar with the equipment: Before operating, you must fully understand the structure, function and operation of the machine. Reading and understanding the operation manual and safety guide of the machine is the basis for mastering the operation skills.

Adjusting Parameters: Adjust parameters such as temperature, pressure, time, etc. according to specific production needs. Correct parameter setting is the key to ensuring product quality and production efficiency.

Standard Operation: Follow the steps in the equipment operation manual to ensure that each step is correct. Avoid impatience and haphazard operation to avoid damaging the equipment or affecting product quality.

Maintain equipment: Perform regular maintenance such as cleaning, lubrication, tightening, etc. This will ensure normal operation of the equipment and extend its service life.

2. Safety Precautions

Wear protective equipment: Wear appropriate protective equipment such as hard hats, safety glasses, gloves, etc. when operating the machine. This will protect the operator from splashes, high temperatures, etc.

Keep the equipment stable: Make sure that it is placed on a stable and firm surface to avoid shaking or tilting. At the same time, it is forbidden to move or adjust the equipment during operation.

Observe power safety: Use power cords and outlets that comply with regulations, and avoid using damaged or aging cords. Check the electrical system of the equipment regularly to ensure safety and reliability.

Avoid overloading: Do not operate beyond the rated load range. Overload operation may result in equipment damage or a safety hazard.

Emergency Stop: In case of abnormal operation or emergency, press the EMO button immediately to cut off the power supply and shut down the equipment. At the same time, report to the appropriate personnel for handling.

Periodic Training: Regular training is provided for operators to improve their operating skills and safety awareness of the punching and ejection machines. This helps to reduce the occurrence of operating errors and safety accidents.

In short, mastering the operating skills and safety precautions of stamping and molding machines is the key to ensuring smooth production. Only through proper operation and maintenance can production efficiency be improved, product quality be guaranteed, and operator safety be ensured.

Latest News

- Powder moulding machine selection guide: how to choose the right equipment for your production needs

- There are many factors to consider when selecting a powder moulding machine to ensure that the equipment selected will meet production requirements. The followi...

- Dressing and forming equipment: a tool to ensure part accuracy and quality?

- Dressing and forming machines play a vital role in the manufacturing industry. Through a series of precise mechanical operations, they ensure that workpieces me...

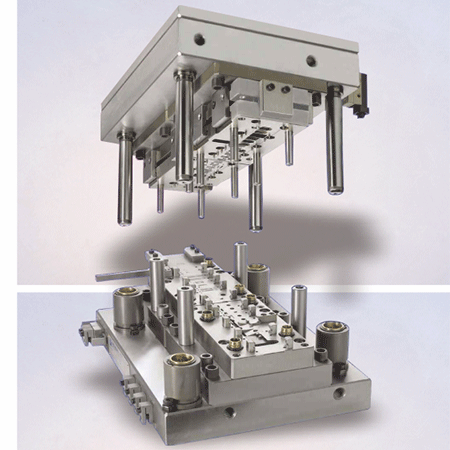

- Powder Metallurgy Mold: A Key Component in the Metal Forming Process

- Powder metallurgy dies are an essential key component in the metal forming process. They use powder metallurgy technology to press metal powder into shape and t...

- Vertical powder forming machine: an efficient and precise industrial manufacturing tool

- In the rapid development of modern manufacturing, vertical powder forming machine, as an advanced manufacturing process equipment, is playing an increasingly im...

- Powder metallurgy mold: the core of efficient metal forming process

- Powder metallurgy mold, as a key component in the metal forming process, is becoming an indispensable and important tool in the manufacturing industry with its ...